A drop-in PCB test fixture, also known as a bed-of-nails test fixture, is a specialized test fixture used to perform functional testing on printed circuit boards (PCBs). It is designed to be easily and precisely placed onto the PCB under test, allowing quick and efficient testing of multiple PCBs in a production or manufacturing environment.

A drop-in PCB test fixture, also known as a bed-of-nails test fixture, is a specialized test fixture used to perform functional testing on printed circuit boards (PCBs). It is designed to be easily and precisely placed onto the PCB under test, allowing quick and efficient testing of multiple PCBs in a production or manufacturing environment.

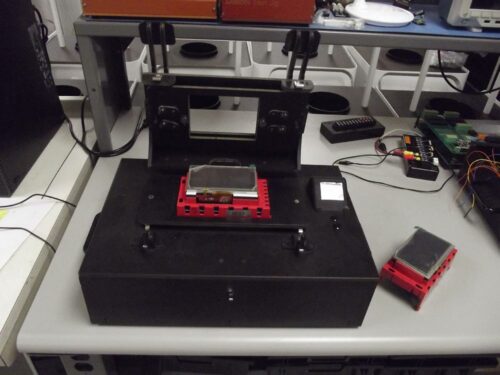

The drop-in test fixture consists of a custom-made fixture with a series of spring-loaded pins, also known as “pogo pins” or “bed-of-nails,” arranged in a pattern that matches the test points on the PCB. These pins make electrical contact with specific test points on the PCB, enabling the test equipment to communicate with the board and perform various tests, such as continuity checks, functional testing, and in-circuit testing (ICT).

Key features and aspects of a drop-in PCB test fixture include:

1. Test Point Alignment: The fixture is precisely designed to match the test points on the PCB, ensuring accurate and consistent contact between the pogo pins and the corresponding test pads.

2. Pogo Pins: These spring-loaded pins provide a reliable and repeatable electrical connection to the PCB during testing. They can accommodate variations in the height of the test points, compensating for any slight board warpage or non-flatness.

3. Customizable Design: The test fixture is customized for each specific PCB design, with the pogo pins arranged in a pattern that corresponds to the test points on the board.

4. Ease of Use: Drop-in fixtures are designed to be easily placed on top of the PCB without the need for complex alignment or manual probing, making them ideal for high-volume production testing.

5. High-Speed Testing: Drop-in fixtures allow for rapid testing of multiple PCBs in a short time, which is especially beneficial for production environments with high throughput requirements.

6. Debugging and Fault Detection: The fixture aids in detecting faults and defects during the manufacturing process, helping identify issues early on and preventing faulty PCBs from proceeding further in the production line.

7. Cost-Effective: Once the fixture is designed and manufactured, the cost per test is relatively low, making it a cost-effective solution for large-scale PCB testing.

Drop-in PCB test fixtures are widely used in electronic manufacturing and assembly processes to ensure the quality and functionality of PCBs before they are integrated into final products. They are an essential tool for automating the testing process, reducing the need for manual testing, and improving overall production efficiency and product quality.